Test Benches development

Soriano Group designs and builds static and dynamic test benches to validate mechanical systems through accelerated testing. By combining simulation, data acquisition, and experimental validation, we ensure reliability, safety, and performance before production.

Test Benches development

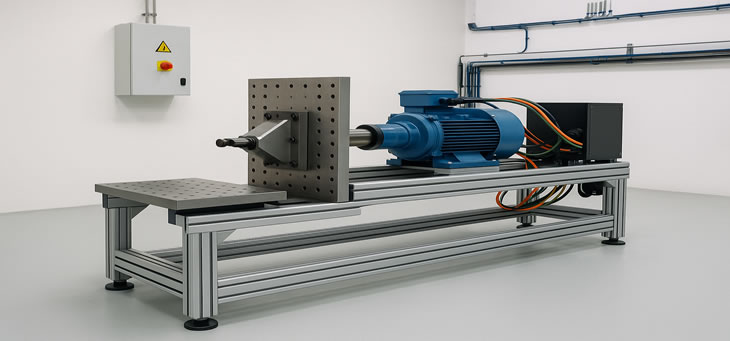

Soriano Group designs and manufactures both static and dynamic test benches for accelerated evaluation of mechanical system functionality over time. These benches play a critical role in the development process by identifying potential failures in prototypes and enabling corrective actions before full-scale production. Verification testing is essential to guarantee product quality, reliability, and safety—especially for mission-critical components.

In addition, Soriano Group brings extensive expertise in data acquisition. Our methodology integrates theoretical modeling, simulation, and real-world experimental validation to deliver accurate insights into system behavior under operational conditions.

We also offer comprehensive reliability analysis services, ranging from failure investigations to CAD-optimized redesigns validated through laboratory and field testing. Our deep knowledge in Failure Analysis, along with advanced capabilities in mechanical design, calculation, and simulation, ensures that our solutions are not only theoretically sound but also validated by practical experimentation.

STATIC TEST BENCH

Design and development of static test benches for validating individual components or mechanical assemblies.

Key Activities:

Analysis of the product and definition of the testing strategy

Design and calculation of kinematic systems to generate appropriate test loads

CAD modeling and execution of structural and kinematic calculations

Selection of suitable commercial components and technologies for construction

Data acquisition during testing: monitoring all relevant physical parameters using dedicated instrumentation

Commissioning support and execution of test procedures

Evaluation of test results and final product characterization

PROCESS TEST BENCH

Process test benches are designed to validate specialized movements and operations in automatic machines or industrial plants. These systems support process technology optimization and subsystem validation (e.g., motion law analysis, cycle time calculation).

Key Activities:

Analysis of the product and operational requirements

Creation of the test bench layout and functional diagrams

Detailed mechanical design and calculation (kinematics and structure)

Component and technology selection for optimal performance

Drafting of technical documentation and compliance with the Machinery Directive (assembly, usage, and maintenance manuals)

Execution of experimental tests

Analysis and characterization of the product based on test results

FATIGUE / DURATION TEST BENCH

Design of automatic test benches for fatigue and wear testing of critical mechanical or commercial components. These benches enable accelerated testing through load definition and simulation under controlled conditions.

Key Activities:

Analysis of product specifications and required testing parameters

Layout and functional diagram creation

Complete engineering design of the test bench

Definition of accelerated test cycles under monitored conditions

Preparation of test control sheets for progress tracking

Integration of automated control and data acquisition systems with remote access for real-time monitoring and data archiving without interrupting test cycles

Execution of experimental tests

Analysis of results and recommendations for product optimization

Technical Expertise & Platforms

PLC – Safety – Motion Control:

Siemens TIA Portal S7-1500 / 1500T

Rockwell Automation Studio5000

Schneider Electric PDM-PD3, Epas4, SoMM, MSE (System Integrator*)

B&R Automation Studio*

Beckhoff TwinCAT 3 (System Integrator)

PLC Platforms:

Siemens S7-300

Siemens TIA Portal S7-1200

HMI Systems:

Siemens WinCC

Rockwell Automation FactoryTalk

B&R VC4 and MappView

Robotics Integration:

Schneider Electric – Robotic NG

Robots integrated within machines and automated systems from:

FANUC

KUKA

Kawasaki

ABB